Forget about the Pacific Northwest or the chilly coast of Maine. Your next piece of salmon could come from the Sunshine State. What was once a sprawling tomato field near the Miami suburb of Homestead is being turned over in stages for a new crop: Atlantic salmon.

The sudden interest in a U.S. salmon production market sparked recently when the price of indoor recirculating aquaculture technology started to fall in line with increasing costs for offshore aquaculture pen operations. The U.S. consumes almost all Atlantic salmon raised in farms. Europe, Chile, and Canada imports about 95 percent of it by plane.

Atlantic Sapphire, a Norwegian company that pioneered technology to farm salmon entirely on land, is building a salmon farm near the southernmost edge of the continental U.S., about an hour’s drive south of Miami.

The company says they’re going to be able to offer a fresher product in the U.S., at a lower price. Because they’re going to avoid the substantial shipping charges that come with sending refrigerated salmon overseas.

South Florida climate may seem like the most unlikely spot to raise the protein-rich, cold-water fish. However, the company says Florida’s unique underground geology and the state’s business-friendly environmental regulations ended up being the perfect mix for its plunge into the U.S. market.

Atlantic Sapphire’s new technology represents the latest step toward farm-raised fish, a practice mired in controversy but growing worldwide. According to the Food and Agriculture Organization of the United Nations, fish farming, known as “aquaculture,” has expanded so rapidly that it now provides half the fish consumed by humans each year.

Atlantic Sapphire’s technique is unique because the salmon go through their entire life cycle in a contained, above-ground, filtered water system.

How will it work?

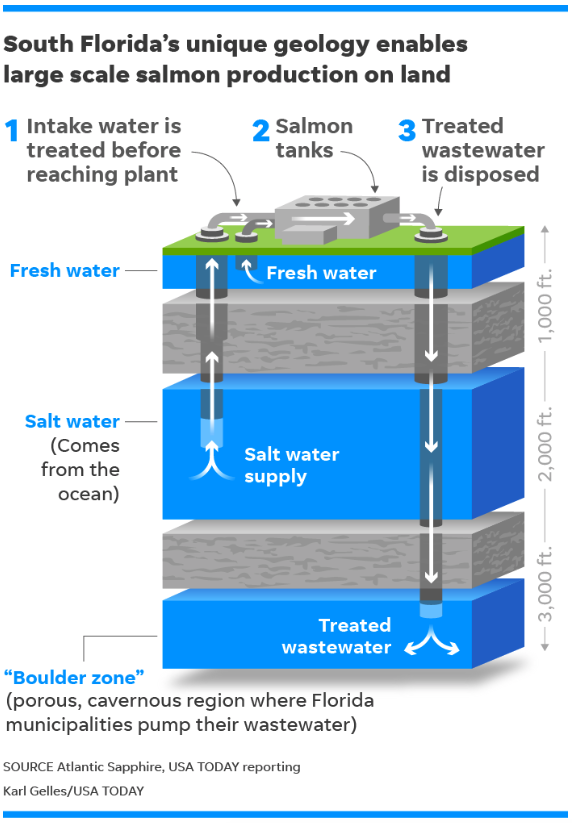

The company is building a series of water tanks connected by 67 miles of pipes. The process starts with smaller tanks for salmon eggs that grow to containers that will hold 450,000 gallons of water each. The water in the tanks is cooled to 59 degrees. It slowly transitions from freshwater to saltwater to mimic the salmon’s natural life cycle. A 400,000-square-foot roof designed to keep out the sun and withstand hurricane-force winds will cover the entire site.

While all that work happens above ground, the key to the project lies underneath. Just underground lies the Biscayne Aquifer, a freshwater reservoir from which much of the region extracts its drinking water. Below that is a layer of impermeable clay, followed by a separate layer of saltwater. Underneath that is another impermeable layer of clay, mud, and rock, followed by a region called the “boulder zone”. That porous, cavernous segment is so deep that many Florida cities already pump their wastewater down there.

If all goes according to plan, Atlantic Sapphire will crank out 10,000 metric tons of salmon by 2020. The company bought 20 adjacent acres of land to expand further and has the option to buy 40 more acres. That would allow the company to produce 90,000 metric tons of salmon a year, about 10% of the U.S. market.

According to a Florida economic-consulting firm, The Washington Economics Group, the company plans a total capital investment of about $585 million. The finished project will support 80 to 100 local jobs. Including engineers, geologists, biologists, veterinarians and the workers that feed, move and process the salmon.